The smart crane and first research topics presented at the Industrial Internet Campus

Research topics include high precision lifting and user identification.

Aalto University Industrial Internet Campus celebrated the inauguration of the smart crane donated by Konecranes on 18 January, 2017. The crane’s smart functions relate to safe operation and condition monitoring.

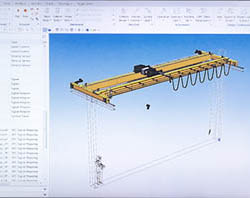

In the crane design Siemens PLM software is used. There new solutions can be simulated with the crane’s digital twin i.e. the virtual copy of the crane and its automation system.

The digital twin develops according to data produced by the physical crane making it an exact replica. The twin can be used for simulations and in product development. Siemens’ CEO Janne Öhmän said in the event that this full loop back from the physical crane to its digital twin and back through product development makes this crane a unique solution worldwide.

Students and researchers will be able to use real world industrial solutions and have access to latest technology at the Industrial Internet Campus. This was also stressed by Konecranes’ CEO Panu Routila in his speech as their aim for the cooperation with Aalto University is to get ideas and access to competent developers and future workforce.

“Ilmatar” was chosen as the name for the crane based on a student competition. Ilmatar is a female air spirit from the Kalevala, the Finnish national epic. Helmi Savolainen got inspiration for her suggestion from Finland’s centenary this year.

Demos

Visitors got to hear about the crane’s smart features and digital services, had a chance to actually operate it and see what kind of live data the crane delivers for the end user. The first research projects around the crane have started at Aalto University.

Student project on User Identification

Aalto students are going to create a fully functioning user identification and monitoring system for the crane. With the system one can control who is allowed to operate the crane and monitor how the crane has been operated by its users.

Research on applying fast prototyping product development philosophy for applications of Industrial Internet

Intention of this research project is to enable high precision lifting through application programmable interface and to develop capabilities of the crane for special needs. The project aims to sharpen the precision to the level of automatic assembly lifting.

Demos also included:

Augmented Reality (AR) Supporting Sales

Konecranes demonstrated an AR solution where the customer has a chance to see how the remote monitoring unit would look like in the customer’s own environment. Augmented reality can bring lots of added value to traditional purchase situations.

Augmented reality (AR) aided industrial maintenance

Augmented reality (AR) aided industrial maintenance

In the Dimecc S-STEP research program (2015-2016) Konecranes focused on augmented reality solutions and real-time contextual information. At the inauguration event they demonstrated one of the AR use cases: CXT electric cubicle and its contextual AR information.

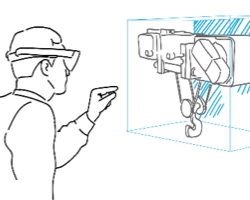

Augmented CXT hoist with Hololens

With the aid of augmented reality, R&D is able to experience the product in real size in any step of the product design process. This will open new possibilities in presenting the design solutions and gathering feedback. Augmented 3D model of the product can be utilized in various purposes during the product lifecycle e.g. for marketing, sales, training or service.

Digital twin and PLM supporting crane development

In this demo visitors got to know the digital twin of the crane in PLM and envision new methods to develop the crane as well as utilize industrial Internet knowledge in PLM environment.

Nokia Innovation Platform

Nokia Innovation platform is a live development and trial environment for startups, industries and other contributors to the IoT. The connectivity kit that Nokia gave as a gift to the Campus provides a wireless connection from the test and development environment to the platform. Read more